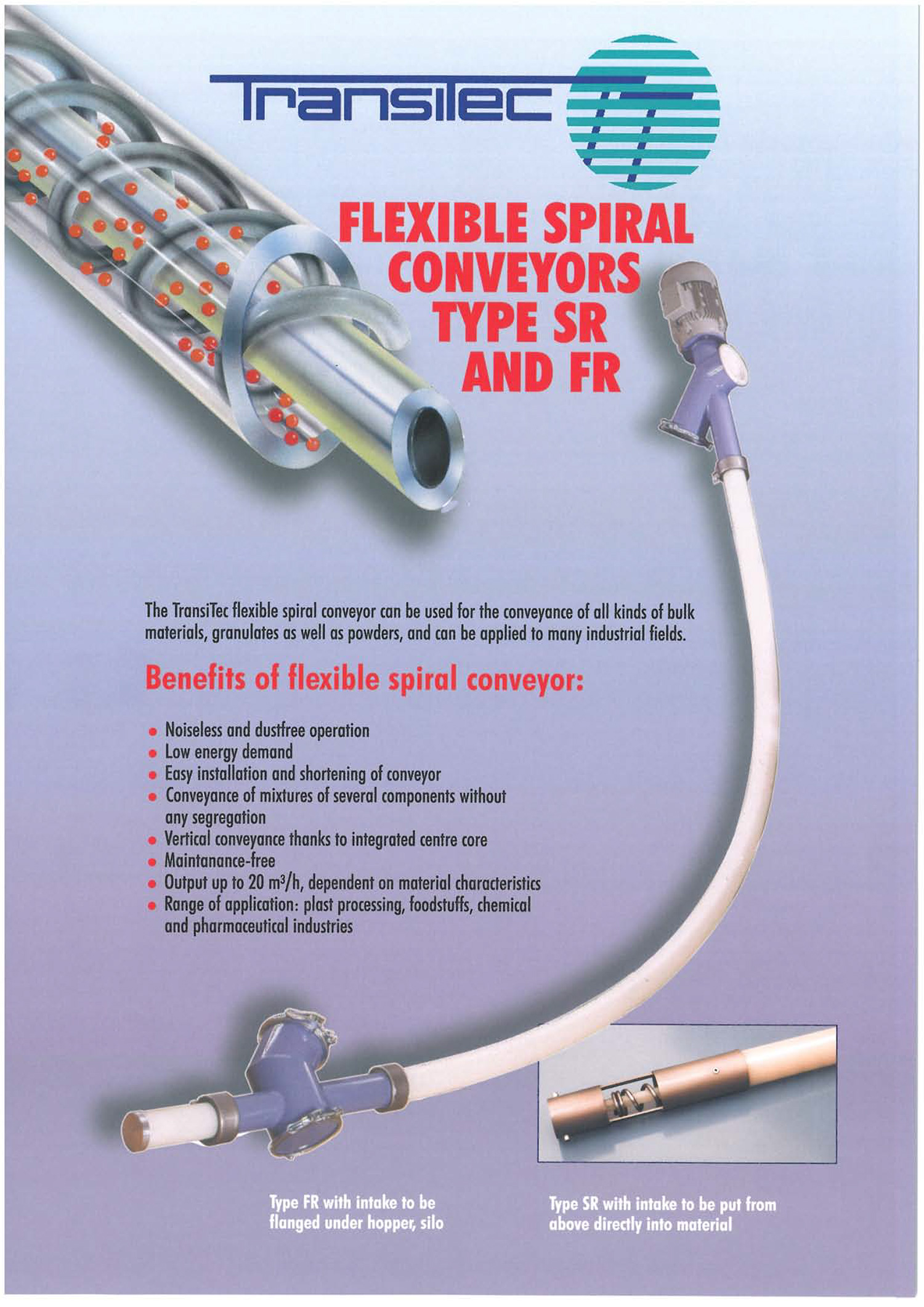

Mechanical Conveying: Spiral Conveyors

Flexible Spiral Conveyors for Dosing into a Weigh Hopper Above a Mixer

This system is designed for the production of bath salts in up to approximately 100 different formulations.

The four main components are dosed into the large weigh hopper using TransiTec flexible spiral conveyors, fed from three big-bag unloading stations and one sack loading station.

For the two smaller components, two sack unloading stations are used, from which the materials are dosed into a smaller weigh hopper via spiral conveyors.

When the mixer located below the weigh hopper is empty, the shut-off valves open, allowing the pre-weighed powder components to be discharged into the mixer.

A liquid fragrance is dosed as needed through a weigh-controlled dosing pump.

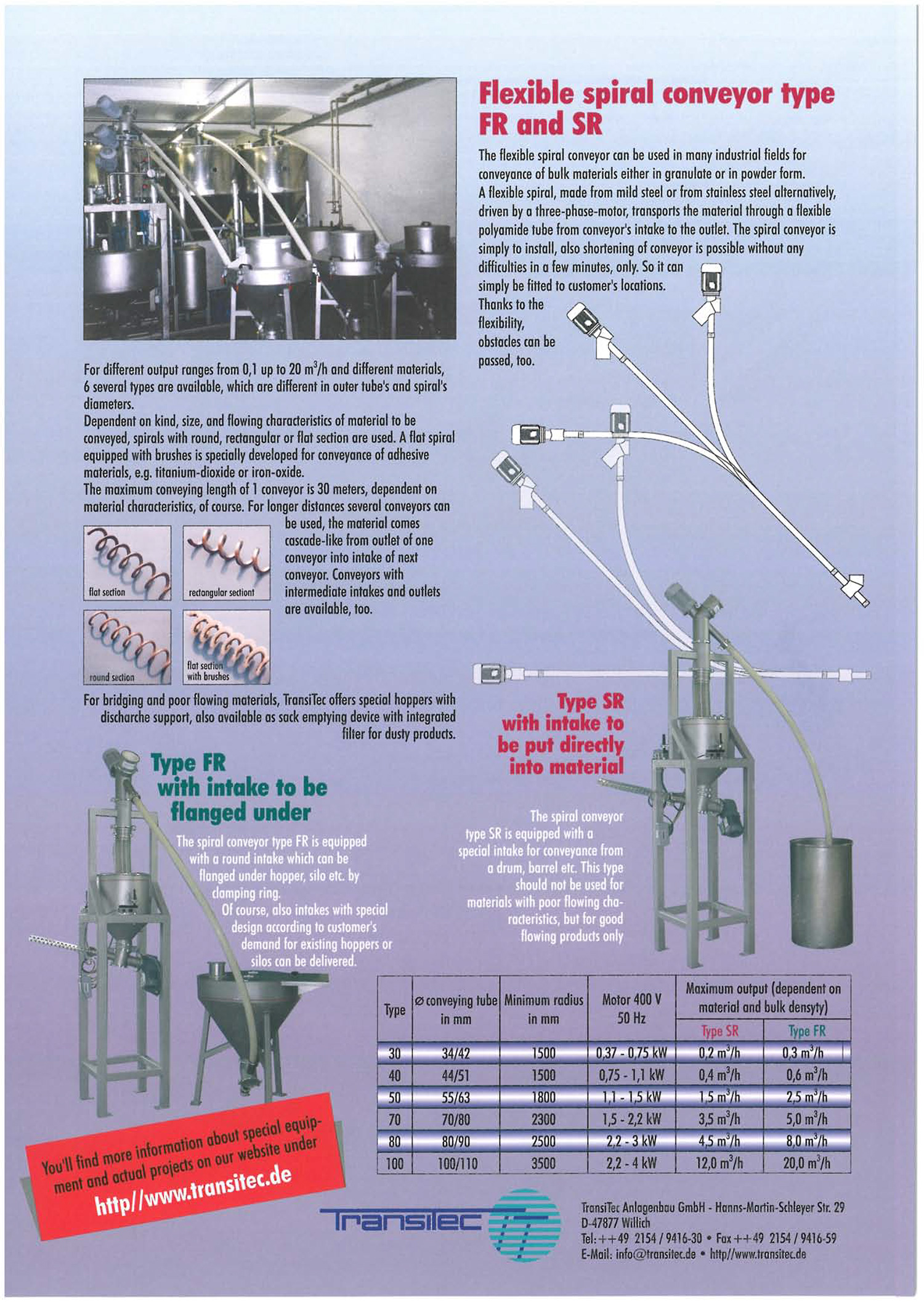

Spiral Conveyors with Rigid Stainless Steel Outer Tubes for Conveying PVC Powder

PVC powder mixtures are initially conveyed from external silos into distributor hoppers suspended in a platform using spiral conveyors.

Each distributor hopper contains a different color mixture.

From each distributor hopper, four extruders located below the platform can be fed with the desired PVC powder mixture using spiral conveyors.

Conveying or Dosing of Various Granulates into a Weighed Mixing Tank

Several types of plastic granulates are sequentially dosed into the weighed mixing tank using TransiTec flexible spiral conveyors.

After mixing, the mixture is conveyed again by a spiral conveyor into a buffer tank.

From the buffer tank, several dosing systems are supplied. (See illustration below).

Feeding Five Dosing Systems from a Buffer Tank Using TransiTec Flexible Spiral Conveyors

Conveying with spiral conveyors ensures there is no risk of demixing!

Cascading Conveyance Using Spiral Conveyors

To overcome longer conveying distances, multiple spiral conveyors can be installed in sequence, cascading the bulk material from one conveyor to the next.

Here, five individual components are fed from a multi-component dosing station into the conveying line.

Proportionally dosed, the components are mixed by the spiral conveyor and simultaneously conveyed to external silos located approximately 150 meters away.

Spiral Conveyor with Curved Stainless Steel Outer Tube

From a discharge hopper of Type DZR, designed for difficult-flowing and bridging bulk materials, plastic film regrind is conveyed upwards to the platform. There, the regrind is fed into the feed hoppers of three gravimetric dosing systems using three short spiral conveyors.

Granular bulk materials are conveyed into the respective feed hoppers of the gravimetric dosing system using vacuum conveyors.

Contact us

We look forward to hearing from you! Get in touch with us to learn more about our solutions and services.

Contact Form:

Simply fill out the contact form, and we will get back to you as soon as possible.

TransiTec Anlagenbau GmbH

Hanns-Martin-Schleyer Street 29

D – 47877 Willich

Phone: + 49 (0) 21 54 / 94 16 – 30

Fax: + 49 (0) 21 54 / 94 16 – 59

Email: info@transitec.de