Big-Bag Emptying Stations

10 Big-Bag Unloading Stations with Discharge Aids for Difficult-Flowing and Bridging Bulk Materials. 6 Big-Bag Unloading Stations for Free-Flowing Bulk Materials.

Feeding of gravimetric dosing systems above two compound extruders.

The difficult-flowing bulk materials are conveyed into the feed hoppers of the gravimetric multi-component dosing stations using spiral conveyors.

The free-flowing bulk materials are conveyed upward using vacuum conveyors.

Weighed Big-Bag Unloading Station with Integrated Chain Hoist

The entire frame is mounted on a base frame with four load cells. In this case, dosing alternates between two blower conveying systems.

To assist with Big-Bag discharge, the Big-Bag collection tray, equipped with a vibration motor, is mounted on four rubber buffers within the frame. The vibration motor is controlled via an empty sensor in the lower product retention hopper.

A lump breaker is also located inside the product retention hopper.

Big-Bag Unloading Station for Free-Flowing PE Powder

Either self-milled powder from a customer-provided impact disc mill or purchased PE powder from Big-Bags is conveyed into two buffer silos located in the adjacent hall using flexible spiral conveyors.

The full Big-Bag is suspended in the frame using a forklift.

The upper frame consists of a tube-in-tube system with springs, which acts as a tensioning device to tighten the Big-Bag. As the Big-Bag empties or becomes lighter, the Big-Bag lifting cross is raised by spring pressure, tightening the Big-Bag at the four corners.

8 Big-Bag Unloading Stations With integrated chain hoists for suspending the full Big-Bags.

Completely made of stainless steel.

Walkable platforms for opening the Big-Bag discharge nozzles.

Big-Bag Unloading Station with Vibrating Big-Bag Collection Tray

Equipped with a Type DZR discharge and dosing system.

Powdered activated carbon is dosed into a dissolving tank via a flexible spiral conveyor.

Double Big-Bag Unloading Station – Combined with Sack Discharge Hopper

Plastic granulate freely flows by gravity either from the left or right Big-Bag into a sack loading hopper below.

The customer has installed a suction box for existing vacuum conveyors beneath the loading hopper.

The height adjustment of the upper frames is limited by the sack loading hopper below.

Therefore, additional height-adjustable chains were provided for suspending Big-Bags of varying sizes.

Big-Bag Unloading Station with Dust Extraction

Due to space constraints, neither a docking device nor a closed housing for opening the Big-Bag discharge nozzle could be used.

As a solution, a system was designed to extract the dust generated during unloading, using either central extraction or a dedicated filter extraction system.

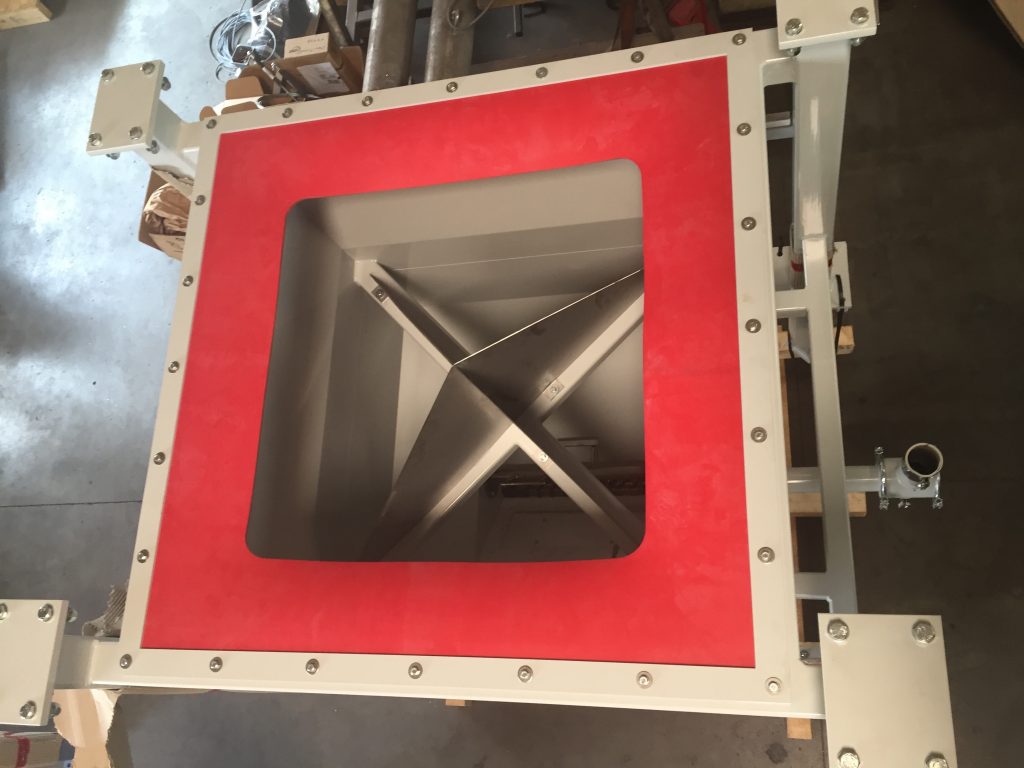

Big-Bag Unloading Station with Knives for Disposable Big-Bags

Big-Bag collection tray with cross-slitting knives for cutting open Big-Bags with closed bottoms WITHOUT discharge nozzles.

Big-Bag Unloading Station for Big-Bags with Fully Openable Bottom

Contact us

We look forward to hearing from you! Get in touch with us to learn more about our solutions and services.

Contact Form:

Simply fill out the contact form, and we will get back to you as soon as possible.

TransiTec Anlagenbau GmbH

Hanns-Martin-Schleyer Street 29

D – 47877 Willich

Phone: + 49 (0) 21 54 / 94 16 – 30

Fax: + 49 (0) 21 54 / 94 16 – 59

Email: info@transitec.de